Revision History

|

Rev. |

Description of Modification |

Date |

|

0 |

1st Submission |

14/09/2022 |

|

1 |

Revised according to IEC’s comment |

20/09/2022 |

TABLE OF CONTENTS

4. Summary of Exceedance, Complants, Notification of Summons and Prosecutions

7. Conclusion and Recommendations

Appendix A Master Programme

Appendix B Overview of Mainlaying in Tseung Kwan O

Appendix C Summary of Implementation Status of Environmental Mitigation (EMIS)

Appendix D Summary of Exceedance

Appendix E Complaint Log

Appendix F Event/ Action Plan for Noise and Landfill Gas

Appendix G Waste Flow Table

A1. Penta-Ocean - Concentric Joint Venture (POCJV) is contracted to carry out the Mainlaying in Tseung Kwan O under Contract No. 13/WSD/16 (hereinafter known as “the Project”).

A2. In accordance with the Environmental Monitoring and Audit (EM&A) Manual for the Project, EM&A works should be carried out by Environmental Team (ET), Acuity Sustainability Consulting Limited (ASCL), during the construction phase of the Project.

A3. The construction works of Mainlaying in Tseung Kwan O were commenced on 30 August 2018. This is the 15th quarterly Environmental Monitoring and Audit (EM&A) summary Report prepared by ASCL. This report presents the EM&A works carried out during the period of 1 February to 30 April 2022.

A4. All the environmental monitoring works were conducted in accordance with the EM&A Manual. The monitoring results were checked and reviewed. Site audits were conducted once per week. The implementation of the environmental mitigation measures, Event Action Plans and environmental complaint handing procedures were also checked.

A5. A summary of the monitoring activities undertaken in this reporting period is listed below:

|

Monitoring Activities |

Frequency |

|

Daytime Noise monitoring |

13 times |

|

Landfill Gas Monitoring |

1414 times |

|

Environmental Site Inspection |

12 times |

A6. All construction noise monitoring was conducted as scheduled in the reporting quarter. No Action and Limit Level exceedance was recorded in the reporting quarter.

A7. No Action and Limit Level exceedance of landfill gas monitoring was recorded in the reporting quarter.

A8. No environmental complaint, noticfication of summons and prosecution was received in the reporting quarter. The Complaint Log is presented in Appendix E.

A9. There were no changes to be reported that may affect the on-going EM&A programme.

1.1. Background

1.1.1. The proposed Desalination Plant at Tseung Kwan O (DPTKO) will produce potable water with an initial capacity of 135 million liters per day (MLD), expandable to an ultimate capacity of 270 MLD in the future to provide a secure and alternative fresh water resource complying with the World Health Organization (WHO) standards. The plant will adopt the Seawater Reverse Osmosis (SWRO) technology, which dominates the market due to its reliability and progressive reduction in cost as the technology advances.

1.1.2. Pursuant to the Environmental Impact Assessment Ordinance (EIAO), the Director of Environmental Protection granted the Variation of Environmental Permit (No. EP-503/2015/A) to Water Supplies Department (WSD) for the Project on 26 January 2018.

1.1.3. The scope of the Contract may be considered in brief, to consist of the laying of about 10km long 1200mm diameter freshwater mains and the associated works along the alignment of the Project as shown with the overall view in Appendix B.

1.2. The Reporting Scope

1.2.1. This is the 15th Quarterly EM&A Report for the Project which summarizes the key findings of the EM&A programme during the reporting period from 1 February 30 April 2022.

1.2.2. Contact details of the key personnel are presented in Table 1.1 below:

Table 1.1 Contract Details of Key Personnel

|

Party |

Position |

Name |

Telephone no. |

|

Penta-Ocean-Concentric Joint Venture |

Environmental Officer |

Calvin Chik |

9863-5630 |

|

Acuity Sustainability Consulting Limited |

Environmental Team Leader |

Jacky Leung |

2698-6833 |

|

ANewR Consulting Limited |

Independent Environmental Checker |

James Choi |

2618-2831 |

1.3. Summary of Construction Works

1.3.1. Details of the major construction works undertaken in this reporting quarter are shown in Table 1.2. The construction programme is presented in Appendix A.

Table 1.2 Summary of Construction Works Undertaken in the Reporting Quarter

|

Location |

Location |

Works Conducted in the reporting quarter |

|

Portion H of the Project Site |

TKO 137 Pit A |

· Site clearance for pipe jacking works were conducted. · Preparation works of pipe installation inside sleeve pipe between Pit 137A to Pit 137C were conducted. · Pipe installation works inside sleeve pipe between Pit 137A to Pit 137C will be conducted. |

|

TKO 137 Pit B |

||

|

TKO 137 Pit C |

||

|

Portion J of the Project Site |

Wan Po Rd – Workfront 1 |

· Pipe trench excavation and pipe laying were in-progress. · Mini piling works for ELS of receiving pit 1 construction · Curtain grouting works for the receiving pit 1 |

|

Wan Po Rd – Workfront 2 |

· Mini piling works for ELS of jacking pit construction · Curtain grouting for mini piling works of jacking pit 2 · Excavation and ELS works for jacking pit 2 |

|

|

Wan Po Rd – Workfront 3 |

· Pipe trench excavation and pipe laying |

|

|

Wan Po Rd – Workfront 4 |

||

|

Wan Po Rd – Pit A |

· Remedial works for pit |

|

|

Wan Po Rd – Pit B |

· Preparation works for TBM pipe jacking |

|

|

Wan Po Rd – Pit D |

· Completion of Pit D construction. · Preparation works for TBM pipe jacking · MTBM pipe jacking |

|

|

Shek Kok Road – Hand-shield |

· Modification of existing retaining wall · Construction of wing wall |

|

|

Landfill Stage 1 – Area A |

· Pipe trench excavation and pipe laying · Plate load test was conducted. |

|

|

Pet Garden’s Road |

· Pipe trench excavation and pipe laying |

|

|

Landfill Stage 1 – Area B |

· Trench excavation and pipe laying were in-progress. |

|

|

Pung Loi Road – Pit WPR1 |

· Sheetpile driving works for pit ELS · Excavation and ELS works for jacking |

|

|

Roundabout – Pit G1A |

· Pit excavation and ELS works · Complete receiving pit construction |

|

|

Velodrome – Pit K |

· Preparation works for pipe laying · Pipe installation works inside sleeve pipe between Pit K to Pit L |

|

|

Velodrome – Pit L-M |

· Trench excavation and pipe laying works · Pipe installation inside sleeve pipe between Pit M1 to Pit M2 · Hand-shield pipe jacking works were conducted. |

|

|

Velodrome – Pit O to Pit N |

· Trench excavation and pipe laying · Site clearance works |

|

|

Velodrome – Pit O to Pit P |

· Site setup works for trenchless works · TBM pipe jacking works |

|

|

Ling Hong Road – Pit Y |

· Grouting works of cavity between sleeve pipe and MS pipe |

|

|

Ling Hong Road – Pit R |

||

|

Mau Wu Tsai – Workfront 1 |

· Trench excavation and pipe laying works |

|

|

Mau Wu Tsai – Workfront 2 |

||

|

Po Lam Road South |

||

|

Po Lam Road (C2) |

· Pre-drilling works for mini piling of pipe bridge at Location A westside slope |

|

|

Po Lam Road (D2) |

· Trench excavation and pipe laying works |

|

|

Po Lam Road (B4) |

· Trench rock breaking works · Trench excavation and pipe laying works |

|

|

Tsui Lam Road |

· Bamboo platform erection works |

|

|

TKO Primary Service Reservoir |

· Trench excavation and pipe laying works |

1.4. Summary of Construction Works

1.4.1. A summary of the valid permits, licences, and /or notifications on environmental protection for this Project is presented in Table 1.3.

Table 1.3 Summary of the Status of Valid Environmental Licence, Notification, Permit and Documentations

|

Reference |

Validity Period |

Remark |

|

Variation of Environmental Permit |

||

|

EP no.: EP -503/2015/A |

Throughout the Contract |

- |

|

Notification of Construction Works under the Air Pollution Control (Construction Dust) Regulation (Form NA) |

||

|

Ref no.: 423775 |

Throughout the Contract |

- |

|

Chemical Waste Producer Registration |

||

|

WPN: 5213-839-P3287-01 |

Throughout the Contract |

- |

|

Billing Account for Disposal of Construction Waste |

||

|

A/C no.: 7029491 |

Throughout the Contract |

- |

|

Water Discharge License |

||

|

WT00032336-2018 |

Until 31 Dec 2023 |

- |

|

Construction Noise Permit |

||

|

GW-RE1219-21 |

Until 1 Apr 2022 |

Expired in the reporting period |

|

GW-RE0330-22 |

Until 1 Oct2022 |

- |

|

GW-RE1211-21 |

Until 1 Apr 2022 |

Expired in the reporting period |

|

GW-RE0329-22 |

Until 1 Oct2022 |

- |

|

GW-RE1224-21 |

Until 1 Apr 2022 |

Expired in the reporting period |

|

GW-RE0353-22 |

Until 1 Oct2022 |

- |

1.4.2. The status for all environmental aspects is presented Table 1.4.

Table 1.4 Summary of Status for Key Environmental Aspects under the EM&A Manual

|

The baseline noise monitoring result has been reported in Baseline Monitoring Report and submitted to EPD under VEP Condition 3.4 |

|

|

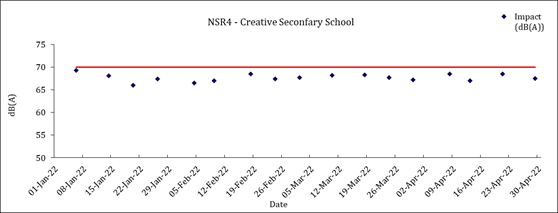

13 times of noise impact monitoring were conducted in the reporting period at NSR4 Creative Secondary School since projected-related construction activities were undertaken within a radius of 300m from the monitoring location |

|

|

On-going |

|

|

On-going |

|

1.4.3. Other than the EM&A works by ET, regular environmental management meetings were conducted in order to enhance environmental awareness and closely monitor the environmental performance of the contractors.

1.4.4. The EM&A programme has been implemented in accordance with the recommendations presented in the approved EIA Report and the EM&A Manual. A summary of implementation status of the environmental mitigation measures for the construction phase of the Project during the reporting period is provided in Appendix C.

2.1. Monitoring Requirements

2.1.1. To ensure no adverse noise impact, noise monitoring is recommended to be carried out within 300m radius from the natby sentitive recivers (NSRs) during construction phase. Referring to the EM&A Manual Section 4.1.2, the impact noise monitoring should be carried out at all designated monitoring stations when there are project-related construction activities undertaken within a redius of 300m from the monitoring stations.

2.2. Monitoring Parameter

2.2.1. Impact noise monitoring was conducted weekly in the reporting quarter between 0700-1900 on normal weekdays. Construction noise level was measured in terms of the A-weighted equivalent continuous sound pressure level (LAeq). Leq 30min was used as the monitoring parameter for the time period between 0700 and 1900 on normal weekdays. Table 2.1 summarizes the monitoring parameters, frequency, and duration of the impact noise monitoring.

Table 2.1 Noise Monitoring Parameters, Time, Frequency and Duration

|

Time |

Frequency |

Duration |

Parameters |

|

Daytime 0700 – 1900 |

Once per week |

Continuously in Leq 5min/Leq 30min (average of 6 consecutive Leq 5min) |

Leq, L10 & L90

|

2.2.2. The monitoring methodology and QA/QC procedure could be referring to Section 2.4 of the Monthly EM&A Report.

2.3. Monitoring Location

2.3.1. According to the environmental findings detailed in the EIA report and Baseline Monitoring Report, the designated locations for the construction noise monitoring are listed in Table 2.2 and shown in Figure 2.1 – 2.3.

Table 2.2 Designated Nosie Monitoring Station

|

NSR ID |

Noise Sensitive Receivers |

Monitoring Location |

Position |

|

NSR4 |

Creative Secondary School |

Roof Floor |

1m from Façade |

|

NSR24 |

PLK Laws Foundation College |

Pedestrian Road on Ground Floor |

Free-Field |

|

NSR31 |

School of Continuing and Professional Studies - CUHK |

Roof Floor |

1m from Façade |

|

|

Figure 2.1 NSR4 Creative Secondary School |

|

|

Figure 2.2 NSR24 PLK Laws Foundation College |

|

|

Figure 2.3 NSR31 School of Continuing and Professional Studies - CUHK |

2.4. Action and Limit Level

2.4.1. The Action/Limit Levels are in line with the criteria of Practice Note for Professional Persons (ProPECC PN 2/93) “Noise from Construction Activities – Non-statutory Controls” and Technical Memorandum on Environmental Impact Assessment Process issued by HKSAR Environmental Protection Department [“EPD”] under the Environmental Impact Assessment Ordinance, Cap 499, S.16 are presented in Table 2.3.

Table 2.3 Action and Limit Level for Construction Noise Monitoring

|

Time Period |

Action Level |

Limit Level |

|

0700 – 1900 on normal weekdays |

When one documented complaint is received from any one of the noise sensitive receivers |

· 70 dB(A) for school and · 65 dB(A) during examaintion period |

|

Notes: (a) Limits specified in the GW-TM and IND-TM for construction and operation noise, respectively. |

||

2.5. Monitoring Results and Observation

2.5.1. 13 times of noise impact monitoring were conducted as schedule in the reporting quarter at NSR4 Creative Secondary School since projected-related construction activities were undertaken within a radius of 300m from the monitoring location.

2.5.2. No construction works were conducted within 300m radius of NSR4 and NSR31. Thus, no construction noise monitoring was carried out at NSR4 and NSR31 in the reporting quarter.

2.5.3. The Graphical presentation of the construction noise monitoring results was shown in Figure 2.4.

Figure 2.4 Graphical presentation of the construction noise monitoring at NSR4

2.5.4. No Action and Limit level exceedance of construction noise monitoring was recorded in the reporting quarter. Summary of Exceedance could be referring to Accpendix D.

2.5.5. If non-compliance occurred, actions as stated in Appendix F will be undertaken.

2.5.6.

The major

noise sources identified at the designated noise monitoring station were

vehicle movement near the Creative Secondary School.

3.1. Mitigation measure on waste management have been implemented in accordance with the requirements of the EM&A Manual. Suitable C&D materials were reused on-site, while the remaining C&D materials and non-inert wastes were disposed at the public filling reception facilities and the landfills respectively. The quanties disposed in the reporting quarter could be referring to Appendix G.

4. Summary of Exceedance, Complants, Notification of Summons and Prosecutions

4.1. All construction noise monitoring was conducted as schedule in the reporing quarter. No Action and Limit Level exceedance was recorded in the reporting quarter.

4.2. Landfill gas monitoring was carried out by the Registered Safety Officer of the Contractor at the excavation locations and within the consultation zones. No Action and Limit Level exceedance was recorded in the reporting quarter. Summary of Exceedance could be referring to Accpendix D.

4.3. No environmental complaint, notification of summons and prosecution was received in the reporting quarter.

5.1. Site inspections were carried out on a weekly basis to monitor the implementation of proper environmental pollution control and mitigation measures under the Contract. Three joint site inspections with IEC were carried out on 24 February, 24 March, 25 April 2022.

5.2. Minor deficiencies were observed during weekly site inspection. Key observations during the site inspections are summarized in Table 5.1 – 5.3.

Table 5.1 Site Observations (February 2022)

|

Date |

Environmental Observations |

Follow-up Status |

|

11 February 2022 |

1. Drip tray should be provided for chemical storage at Pit X. 2. To review water mitigation measure at piling area (Pit X). 3. Regular clear the rubbish in storm drainage to avoid blockage at Pit X. |

1. Chemicals were removed. 2. Sandbags was provided to direct surface runoff to wastewater treatment facilities. 3. Rubbishes in storm drainage were cleaned. |

|

17 February 2022 |

1. Gullies were observed not protected by sandbags/geo-textile on 4 sides at Wan Po Road 3. |

1. Gullies were protected by geo-textile. |

|

24 February 2022 |

1. Drip tray should be provided for chemical storage at Pit D. 2. To establish tree protection zone at Pit D. 3. Wastewater should be properly treated before discharge at Pit A and workfrount 4b. 4. To clear stagnant water in drip tray (Pit A). 5. Gully should be covered and provide sandbags around the gully to avoid muddy surface runoff flow into gully. (WorkFrount 4) |

1. Chemicals were removed. 2. Tree protection zone was established at Pit D. 3. There was no wastewater discharged at Pit A and workfrount 4b. 4. Stagnant water in drip tray was cleared. 5. Gully was covered by geo-textile. |

Table 5.2 Site Observations (March 2022)

|

Date |

Environmental Observations |

Follow-up Status |

|

3 March 2022 |

1. Clear the oil stain on ground and avoid oil leakage from excavator. (Po Lam South Road) |

1. The oil stain on ground was cleaned. |

|

11 March 2022 |

1. Drip tray should be provided for chemical storage. (Wan Po Road Workfount 4) 2. Stockpile of dusty materials should be covered properly with impervious materials at Area A. |

1. Chemical was removed 2. Dusty materials was covered properly. |

|

18 March 2022 |

1. Drip tray should be provided for chemical storage. (Pit P and Velodrone O) 2. Adequate capacity of sedimentation tank should be provided to prevent overflow of untreated muddy water at Velodrome L. |

1. Drip tray was provided for chemical storage. 2. Sedimentation tank was cleaned. |

|

24 March 2022 |

1. Chemcial waste should be stored at a designated area before disposal. (Creative School) 2. Excavated materials/ rubbish should be disposed of properly and prevent soil entering the stream. (Creative School) |

1. Chemical waste was cleaned. 2. Excavated materials/ rubbish was cleaned. |

|

30 March 2022 |

1. Drip tray should be provided for chemical storage (Velodrome L, N, O) 2. To clear the stagnant water in drip tray. (Velodrome L, N, M) |

1. Drip tray was provided for chemical storage. 2. Stagnant water in drip tray was cleared. |

Table 5.3 Site Observations (April 2022)

|

Date |

Environmental Observations |

Follow-up Status |

|

8 April 2022 |

1. Drip tray should be provided for chemical storage. (HK Velodrome N) |

1. Drip tray was provided for chemical storage. |

|

14 April 2022 |

1. Drip tray should be provided for chemical storage. (Pit D) |

1. Drip tray was provided for chemical storage. |

|

21 April 2022 |

1. Drip tray should be provided for chemical storage. (Pit X and Location A) 2. Public road should be cleaned properly and regularly. (Po Lam South Road) |

1. Drip tray was provided for chemical storage. 2. Public road was cleaned properly. |

|

25 April 2022 |

No observations were recorded on the respective day. |

|

5.3. According to the EIA Study Report, Environmental Permit, contract documents and EM&A Manual, the mitigation measures detailed in the documents should be implemented as much as practical. An updated Implementation Status of Environmental Mitigation Measures (EMIS) is provided in Appendix C.

6.1. Monitoring Requirements

6.1.1. In accordance with Section 11 of the EM&A Manual, monitoring of landfill gas is required for construction works within the 250m Consultation Zone. Part of the desalination plant and the indicative area of natural slope mitigation works fall within the SENT Landfill Extension Consultation Zone; and part of the 1,200 mm diameter freshwater mains along Wan Po Road falls within the SENT Landfill and SENT Landfill Extension Consultation Zones, TKO Stage II/III Restored Landfill and TKO Stage I Restored Landfill Consultation Zones.

6.2.1. Monitoring of oxygen, methane, carbon dioxide and barometric pressure was performed for excavations at 1m depth or more within the Consultation Zone.

6.2.2. During construction of works within the consultation zones, excavations of 1m depth or more was monitored:

· At the ground surface before excavation commences;

· Immediately before any worker enters the excavation;

· At the beginning of each working day for the entire period when the excavation remains open; and

· Periodically through the working day whilst workers are in the excavation.

6.2.3. For excavations between 300mm and 1m deep, measurements should be carried out:

· Directly after the excavation has been completed; and

· Periodically whilst the excavation remains open.

6.3. Monitoring Parameter

6.3.1. Landfill Gas monitoring was carried out to identify any migration between the landfill and the Project and to ensure the safety of the construction, operation and maintenance personnel working on-site, visitors and any other person within the Project area.

6.3.2. The following parameters were monitored:

· Oxygen;

· Carbon Dioxide;

· Barometric Pressure

· Methane;

6.3.3. The monitoring methodology and equipment could be referring to Section 4.5 of the Monthly Reprot.

6.4. Action and Limit Level

6.4.1. Action and Limit Level are presented in Table 6.1.

Table 6.1 Action and Limit Level for Landfill Gas Monitoring

|

Parameters |

Action Level |

Limit Level |

|

Oxygen (O2) |

<19% O2 |

<19% O2 |

|

Methane (CH4) |

>10% LEL |

>20% LEL |

|

Carbon Dioxide (CO2) |

>0.5% CO2 |

>1.5% CO2 |

6.5. Monitoring Reuslt

6.5.1. In the reporting quarter, landfill gas monitoring was carried out by the Registered Safety Officer of the Contractor at the excavation locations for 1414 times. No action and limit level exceedance was recorded in the reportig quarter. The landfill gas monitoring results could be referring to Appendix J of the Monthly EM&A Report.

7. Conclusion and Recommendations

7.1. This is the 15th quarterly Environmental Monitoring and Audit (EM&A) Summary Report prepared by ASCL. This report presents the EM&A works carried out during the period of 1 February to 30 April 2022 in accordance with the EM&A Manual and the requirement under EP-503/2015/A.

7.2. 13 times of noise impact monitoring were conducted in the reporting quarter at NSR4 Creative Secondary School since projected-related construction activities were undertaken within a radius of 300m from the monitoring location.

7.3. No Action and Limit Level exceedance of construction noise was recorded during the reporting quarter.

7.4. No landfill gas monitoring exceedance was recorded in the reporting quarter.

7.5. Weekly environmental site inspection was conducted during the reporting quarter. Minor deficiencies were observed during site inspection and were rectified. The environmental performance of the Project was therefore considered satisfactory.

7.6. According to the environmental site inspections performed in the reporting quarter, the Contractor is reminded to pay attention on maintaining site tidiness and proper materials storage. The Contractor is also reminded to consider the treatment of wastewater from the construction site area.

7.7. No environmental complaint, notification of summons and prosecution was received in the reporting quarter.

7.8. The ET will keep track on the construction works to confirm compliance of environmental requirements and the proper implementation of all necessary mitigation measures.

7.9. Statistics on complaints and regulatory compliance are summarized in Appendix E.